Karlatornet: Efficient production with digitized construction logistics

BACKGROUND – THE PROJECT & CHALLENGES

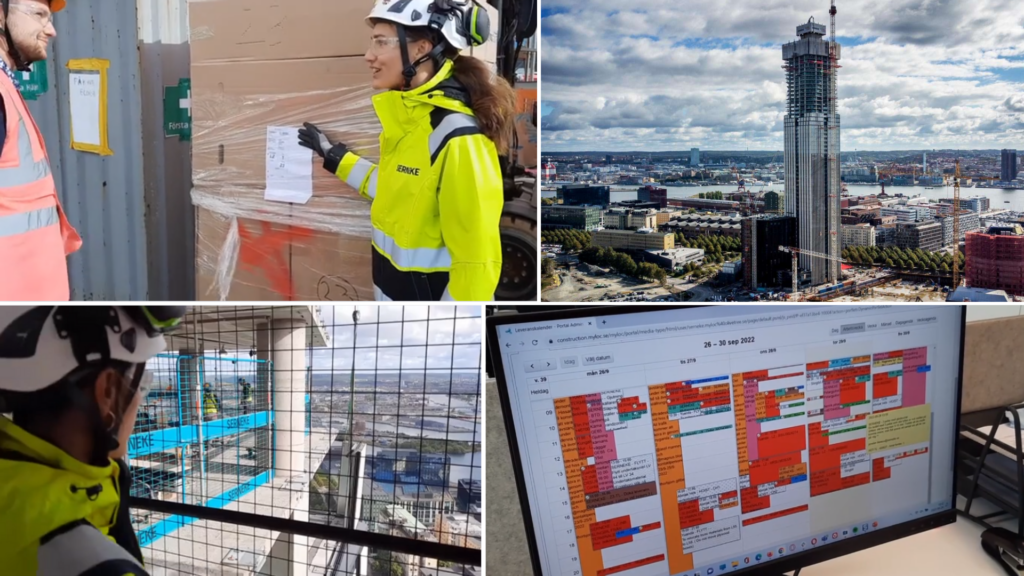

Karlatornet (the Karla Tower) is a core part of the new city development on the island of Lindholmen in Gothenburg known as Karlastaden (the Karla City). Swedish construction company Serneke managed the Development and EPC.

Karlatornet is the tallest building in the Nordic Countries at 246 m and is the first and largest building in the Karlastaden development plan. The construction of the tower alone covered 100,000 m2 in total.

The challenging combination of a tightly spaced urban construction site, limitations posed by the required vertical transports, and the desired speed of construction identified the need for logistical management capability as a key part of the project setup from the very start.

“Karlatornet is the first stage of our development project here in Karlaststaden and it will be the tallest building in the Nordics” Elin Pettersson, Construction Engineer for Logistics at Serneke, introduces the project.

“Altogether, we have a construction area of 100,000 m2 that we are developing here. It’s very tall and very narrow. A lot to be completed at once. After all, each floor in the tower is 1000 square meters, so there are extremely large amounts of materials that need to be fitted in a very short amount of time. And there are the construction lifts, which are one of our bottlenecks. The reason why it’s so complex in terms of logistics and why we have such good help from Myloc is also because we’re working on approximately 43 floors at the same time. Roughly, we have delivered one finished floor a week.”

ASSIGNMENT – MEETING THE DEMANDS OF A HIGH-RISE BUILD

To meet these challenges Serneke teamed up with Myloc in a partnership surrounding the following areas.

- Design of the logistics setup, with detailed:

-

- Logistics flow.

- Organization.

- Roles and responsibilities.

-

- Definition and implementation of logistical terms for use in contracts with contractors and suppliers.

- The Myloc Construction digital platform – Configuration and deployment.

- Myloc Intelligence – Statistics and reports to enable in-depth analysis.

- Integrating material suppliers in Myloc Construction.

- Training and technical support for Myloc Construction Super Users.

- Support for Serneke throughout the project.

THE SOLUTION DESIGN – LARGE VOLUMES, A FAST-PACED CONSTRUCTION PHASE & VERY LIMITED SPACE

The high demands on managing the bottlenecks hindering access to the constricted project site, and the required speed of construction, called for a comprehensive solution. In response, the initial analysis and project setup were incorporated into a detailed logistical strategy described in a Logistics Plan that covered:

- The decision that all logistic activities and deliveries for contractors and suppliers must be planned and managed through one digital platform: Myloc Construction.

- Individual, but harmonized, logistics protocols for foundation, frame and interior construction provided all disciplines with clear guidelines.

- Virtually all materials for the interior build were arranged to be delivered via a Consolidation Centre (short-term 5-10 days storage). Exceptions were made for direct deliveries with fully loaded trucks where loads could be utilized within 24 hours.

- All logistics on-site were set up to be managed by a dedicated central team, with key processes involving:

-

- Checkpoint.

- Un-loading.

- Transportation to installation points.

- All materials delivered as labeled packages.

-

- Implementation of a planning scheme for “package materials”.

-

- 24–48-hour delivery batches.

-

- Separations based on time of day or day of the week (nights, weekends) and placement (e.g. dedicated lifts for certain time slots).

- Strict planning regime.

IMPLEMENTING A LOGISTICS SOLUTION IN A DEMANDING PROJECT

One critical success factor was the implementation of the Logistics Plan for all involved actors. Consequently, the Logistics Plan was included in contract terms with all contractors and relevant suppliers.

During the entire procurement process contractors were invited to presentations and encouraged to discuss the Logistics Plan to ensure a distributed ownership. All contractors and suppliers were gradually integrated and as volumes grew routines were further streamlined.

Maintaining a high level of ambition in terms of quality and adherence to procedures throughout the implementation proved valuable. As the procedures were established, the logistics increasingly developed into a self-playing piano.

“Already at an early stage, we realized that we wouldn’t be able to build this if we didn’t have a logistics solution like Myloc and our logistics plan. So, that was one part of the digitization of this construction, which we’ve come to see is very important. Myloc is a major component of the project and our entire delivery flow, the complete logistics flow, can be found in Myloc.” Elin from Serneke describes the logistics solution, and how the Myloc Construction platform was utilized.

“We use Myloc partly as an Order System, and as a way to integrate the suppliers, including the sub-contractors who order their materials in Myloc. And it makes it easier, above all, to manage the material. Goods arrive at the project site already labeled from the suppliers, and that’s how far back the supply chain flow starts with Myloc. Primarily, gathering everyone and everything concerning deliveries in the same place, and the overview that gives us, has been important. And the Myloc calendar is crucial to us. It is invaluable to see clashes around deliveries since we also use Myloc to plan the booking of resources when we book, for example, a telehandler only in production in the afternoon. That may collide with a delivery coming from the Consolidation Centre. We then identify and manage that through Myloc, so we use Myloc to a high degree of its capacity I would say.”

PROJECT EXECUTION – THE CHARACTERISTICS OF STREAMLINED LOGISTICS EMERGE

The functionality for integrating the supply chain and the site logistics created significant benefits throughout the project. Responsibility could easily be distributed to all contractors, maintaining transparency, control and effortless progress sharing.

- Slot time management, for loading zones and resources, aided in instituting the rigorous logistical routines.

- Specific material management routines for interior construction.

-

- Only materials with agreed label formats were accepted on-site.

- Materials were received, unloaded and transported to the final point of installation by the logistics team.

- App-based reporting of logistical processes during all stages of construction was handled through Myloc Construction GO.

- No materials were received or transported by construction workers or other contractors, only by the logistics team.

- No materials were stored for more than 48 hours on-site.

- The majority of all materials were delivered through the Consolidation Centre, reducing last-mile deliveries by more than 60%.

-

- Full and automatic track and trace capabilities for all stages of the construction production process.

DESPITE THE CHALLENGES – FINISHING THE PROJECT ON TIME & ON BUDGET

The Karlatornet project faced major obstacles with progress implications such as the global pandemic outbreak and a change in ownership during the final stages of construction. After the restart in 2021 with groundwork and garage floors in place, the actual construction of the tower could begin.

246 meters later, the project was delivered on time and within budget during the summer of 2024.

Incidents and injuries at less than industry average and a substantial reduction of transports (both long haul and last mile) were other examples of achievements. The project also generated multiple valuable experiences and observations in many areas, including logistics management.

OBSERVATIONS & LESSONS LEARNED

- The solution was initially considered ambitious with some project participants questioning whether it would even be possible to perform at the planned speed.

- (Sub)Contractors tend to ask for flexibility – but the flexibility of more ad-hoc production strategies creates vulnerabilities that lead to overall losses in time and productivity.

- Financial incentives (positive and negative) work and facilitate results with a higher level of compliance.

- Separation in time and/or space of personnel movements and material flow eliminated potential clashes and improved project progress.

- The involvement from PMO’s as well as subcontractors is critical – efficient logistics require adequate input.

- Ownership of logistics management resources was a crucial factor for success. Delegating to logistics sub-contractors would not have been sufficient for a project of this magnitude.

A FEW FACTS ABOUT KARLATORNET

- The logistics team amounted to ca 2% of the total project cost.

- The Consolidation Centre, with transports and logistics equipment, constituted approx. 0.6% of the project cost.

- In total, the project involved 350 Myloc Construction system users (counting all user categories).

- Deliveries amounted to more than 30,000 individual transports.

- The total number of deliveries were reduced by 40% by use of the Consolidation Centre.

LEARN MORE

Find out more about the practical applications of this logistics solution in the video series ‘Tornet’ from Serneke. Click here to learn more about Myloc Construction and our projects, or contact us at info@myloc.se.

Quotes and images sourced from Myloc’s video presentation of the Karlatornet project, and exterior view graphics property of Serneke.